A Very 3DP Christmas ~

Hope everybody had a lovely, COVID-safe Christmas!

I like making handmade presents (see the $0 sledgehammer) but having only a 3D printer to work with made things significantly… lamer. Anyways, as proof of my continued existence, here’s a few 3D prints I made.

#1a: Puppy Dishwasher Holder

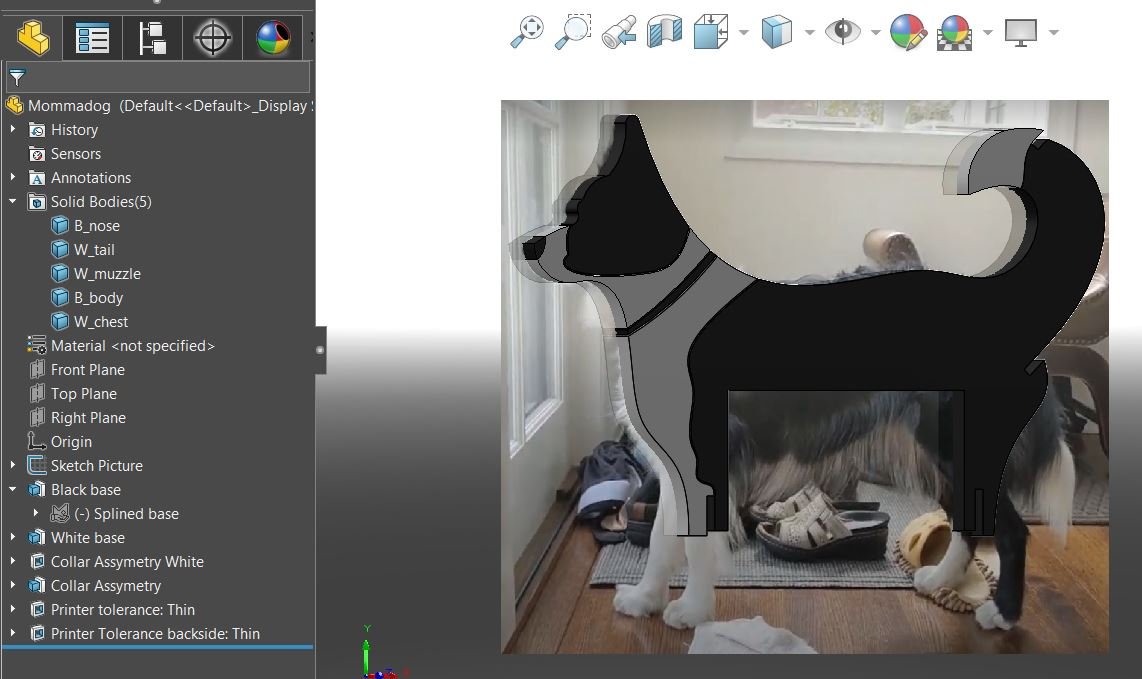

My parents mentioned they wanted a widget to hold open the dishwasher door and mark whether the washer is clean or dirty. There’s a few places online to buy things like that, but I thought it would be fun to make my own modeled after their border collie, Poppy, whom they adopted on Dec 23, 2020. The finished present would celebrating one year with the pup with a useful item they could see and interact with daily!

My parents’ very cute border collie, Poppy!

Cat dishwasher holder by Etsy seller 'Steerheaddesign'

I designed the print to be made out of multiple white & black 3D prints that glue together to match a minimalist, vector-art representation of her fur pattern. I kept it mostly 2D for simple assembly, but differentiated the left and right side accurately.

I also added features to hold a rubber bumper cut from some 40A adhesive-backed neoprene sheet to prevent stratching the dishwasher or countertop. This also allowed a slight undersizing of the interface to assure a secure fit on the dishwasher. Overall the design of the part took about an hour (unincluding half an hour of tricking the dog into taking a decent reference photo to use as a sketch picture).

The prints took ~5 hrs to run (unincluding misprints) and 30 minutes to glue cleanly.

#1b Dog Ornament

I also wanted to make a present for my sister, who really likes dogs but is working 600km away in SF so she can’t see the dog often. I repurposed the design of the dishwasher holder while fleshing out the rest of the puppy that got cut off to accomodate the dishwasher. There’s also a small hook on top.

The nose part misprinted due to its small footprint / high aspect ratio so I replaced it with two pieces of cut black filament! In the future, this can be avoided by flattening the top of the nose (it has a slight arc currently) and print it with that side down.

#2 Plant Pot

My sister really likes plants so I found her a cute thingiverse plant pot that I thought could stand out on her desk. I used some Waterproof woodglue to increase the longevity of the water-holding surfaces while printing out of cheap PLA.

#3 RC Car Repairs

I got my Dad an RC car in the hopes the dog could chase it to tire her out. She’s still getting used to it, as she’s easily spooked by mechanical noises, but we hope it will be a fun playmate in the future. Unfortunately, while test-driving it, we discovered the exposed front shock frame is incredibly weak, which caused it to break, so I made a few revisions of 3D prints to replace it.

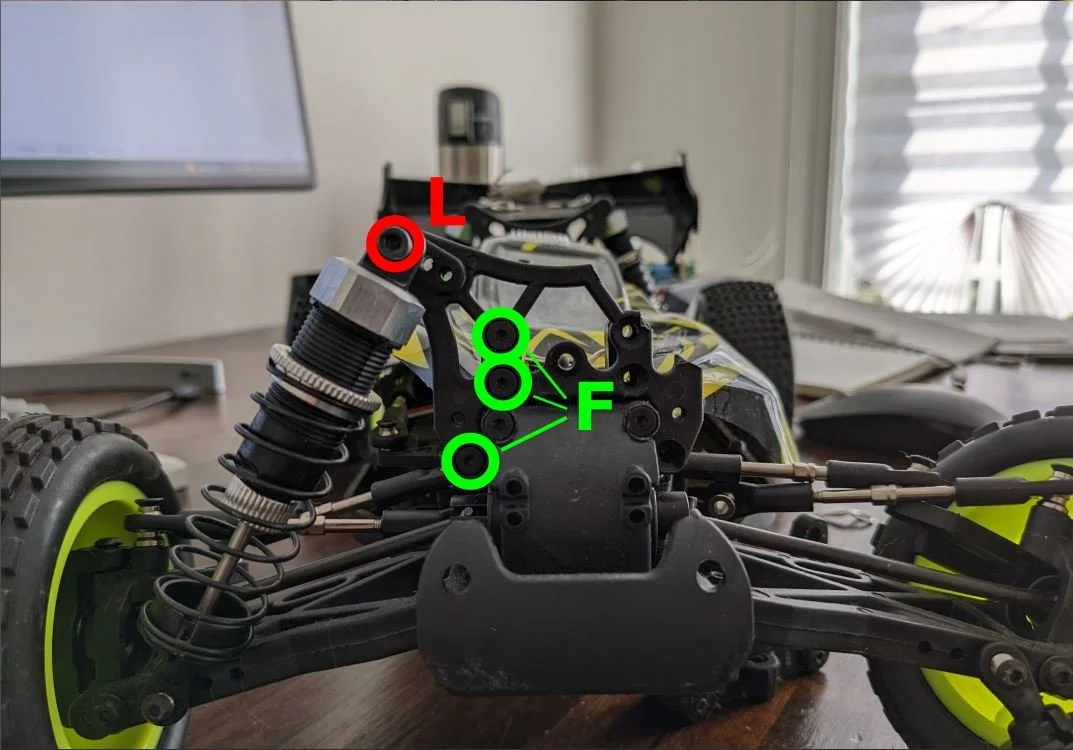

The original suspension mount, set up with the starboard half of the suspension mounted to illustrate the fixtures and load points. Fixturing bolts are marked F and loading locations are marked L.

Loading force (L) and moment (M) created by impact on shocks viewed normal to the plane created by the loading force and fixturing screws (F).

These images illustrate the load condition of the suspension mounting bracket. The bracket is comically undersized and broke as soon as the car ran into something that hit the shock.

Original injection-molded part:

The part’s mounting geometry was centered at the bottom-left of the above view, which was easily replicable. It was minimally possible to to thicken the design in either direction: thickening towards the rear of the car was limited by the car’s geometry, and towards the front bumper is limited by the movement of the front shocks.

Mounted view of the original injection-molded part.

First 3D-printed iteration:

Geometry of the original part was mimicked & part was thickened & reinforced where possible to better handle the moment loads.

The part failed during an identical load situation to the original, which caused the reinforcement part to pop off due to weaker inter-layer adhesion (a property of almost all 3D prints which causes anisotropic failure strengths). The reinforcement not operating correctly allowed the main geometry to fail along the same line as the original.

Mounted view of the first 3D-printed iteration.

Current Iteration:

Identical to the first printed iteration except bolts were added normal to the plane of printing to preload the weakly adhered layers. These bolts, in combination with the mounting bolts of the front suspension, make the reinforcing back much more structurally sound.

Mounted view of the current 3D-printed iteration.

#4* Exercise parallettes

*This isn’t christmas related but its another <10hr 3D print so it kinda fits???

I’ve been exercising a lot lately, and a set of parallettes to allow full-range-of-motion incline pushups would be really useful. I don’t have a inclined exercise bench, so incline pushups are the most effective upper-chest exercise I have access to, but they’re difficult to do to full depth without a few extra inches of space.

The body of them is composed of a 2” round dowel, with 3 3D-printed parts to form a solid base. The vertical ‘A’-shaped parts support the entire weight, and are rubber-padded as to not scratch interior floors or slip during exercise. The central part is simply to hold the whole thing rigid.