Design Consultancy

Consultancy at Smoodi

I worked for 5 months as a part-time consultant for a blended beverage machine startup based in Boston.

My responsibilities ranged from

Redesigning blending interface to minimize cleaning time and comply with food safety standards

Review and inform future industrial and graphic design efforts

Collaboration with consultants & cofounders

Product Refinement Effort

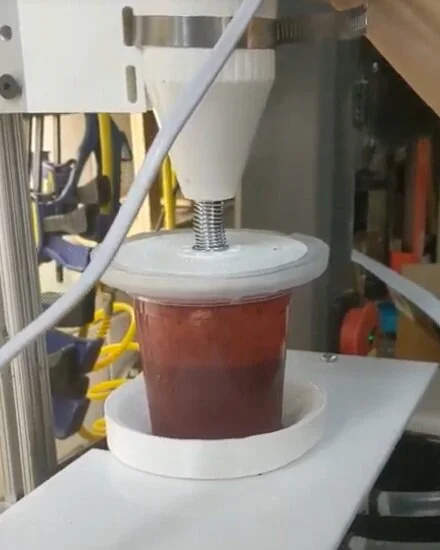

The bulk of my work was refining the core blending system from the prototype into a self-cleaning, food-safe system.

Every week I led the design, fabrication, and testing of a new iteration of the subassembly. Over time our prototypes grew from handheld blenders with basic 3d prints to multipart assemblies mounted on 80/20 rails with linear sliders, to fully food-safe silicon over-molded assemblies, fully waterproofed and plumbed for machine integration.

Vacuum-degassed casting processes used for consistent

Multilayer seals and gaskets

Printed nozzle design and layout tuned to ensure efficient cleaning

User-centric safety shield redesign

Old Design

Top of cup not sealed-entire tube needs cleaning after each blend

90s, 10+ L of water to visual clean

~3000 cm3 of volume to clean

Obscures cup to user with large seal

High partcount & assembly tuning required

New Design

Top of cup sealed during blending: single surface to be cleaned

<10s, 1L of water to visual clean

250 cm3 volume to clean

Shows blending process to user

Reduced partcount, no tuning / configuration

1. Blending

2. User takes smoothie

3. Cleaning

4. Ready for next blend!

Industrial Design

I also helped with industrial design and system-level architecture efforts.

Shown are some of my latter stage industrial design sketches to explore different form factors, materials, and stylings.

Teamwork

Working with engaging and dynamic groups is the best.